Products

Best Famous Stamping Die Components Manufacturer – Sheet Metal Fabrication Laser Cutting – Excellent Intelligent Equipment

Best Famous Stamping Die Components Manufacturer – Sheet Metal Fabrication Laser Cutting – Excellent Intelligent Equipment Detail:

Products Description

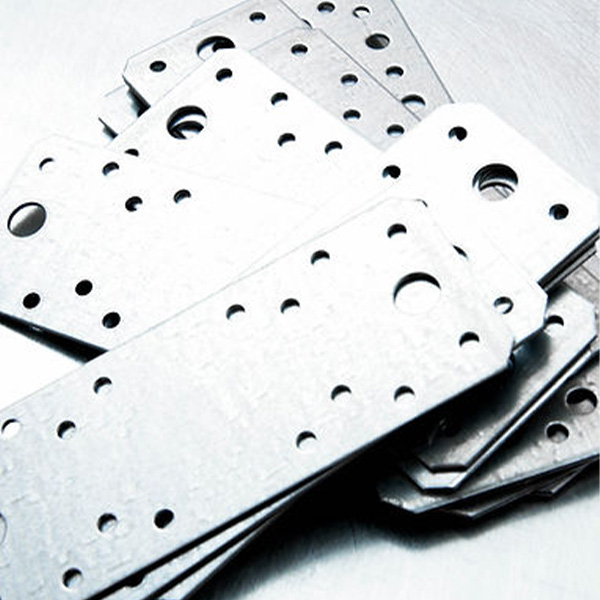

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling.

Key Features:

Laser cutting:Laser cutting is the preferred option for cutting sheet. A very quick and precise cutting method that guarantees good results.

Bending:When it comes to actual engineering, there aren’t many metal components that elude the bending section of a fabrication shop. Press brakes are responsible for the folding of sheet metal parts.This is probably the most difficult step in metal manufacturing because of the complexity of some bends. An engineer must be well acquainted with the limitations of metal bending to things that are actually producible.

Assembling:Assembling is the ultimate or penultimate step when you want to fabricate a product. If assembling includes welding, the parts have to be clean – powder coating follows it.Otherwise, parts are already powder coated and adjoined using other methods, like riveting and bolting.

Powder Coating:Powder coating is a process where an electrostatic powder is applied to a charged metal component. It is the preferred surface treatment method when no special requirements, like wear-heavy or acidic environments, apply to the construction.

Sheet metal fabrication processes are suitable for a gradual transition from prototyping to large-scale production. Making prototypes sets the baseline and expectations for larger quantities by establishing the required infrastructure.

Looking around, it is clear that sheet metal has a plethora of applications. There aren’t many home appliances, constructions, etc. that don’t incorporate any sheet metal parts. Still, different sheet metal groups have some specific uses. And we can go over them.

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for Best Famous Stamping Die Components Manufacturer – Sheet Metal Fabrication Laser Cutting – Excellent Intelligent Equipment , The product will supply to all over the world, such as: Bulgaria, New York, Armenia, We are increasingly expanding our international market share based on quality products, excellent service, reasonable price and timely delivery. Please contact us at any time for more information.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!